Greetings,

While modeling in Sofistik and reviewing the results for the crack width calculation at SLS QP, I noticed an inconsistency that I would like to clarify.

For the effective reinforcement ratio, I computed:

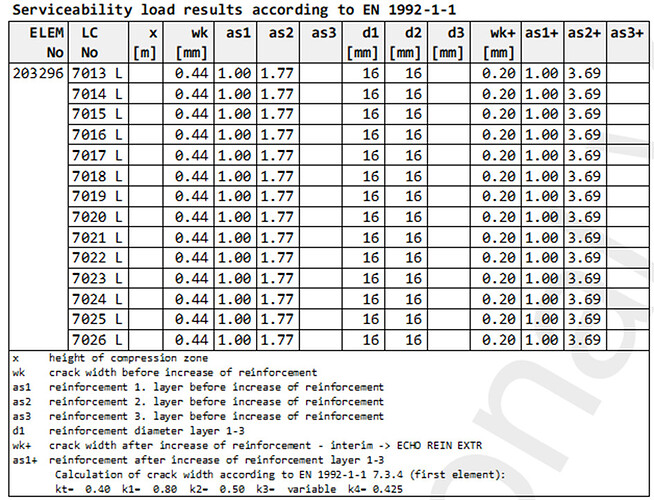

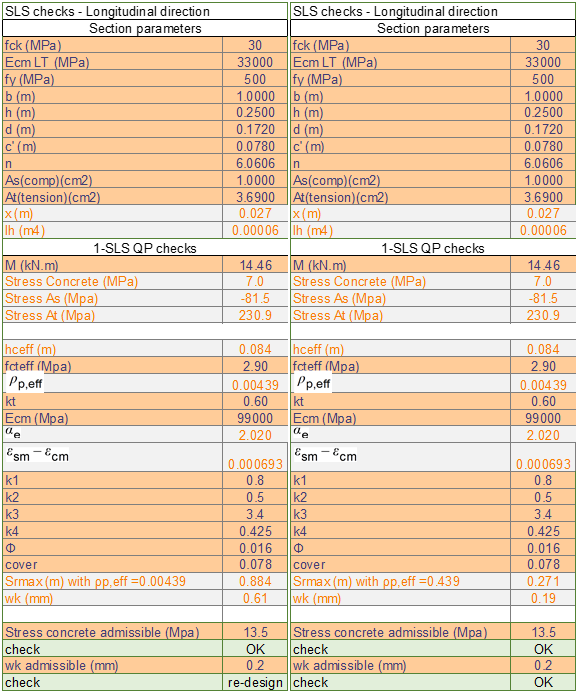

ρp,eff=Asl/(heff⋅b)=(3.69⋅0.01⋅0.01)/(0.084⋅1)=0.00439=0.439 %

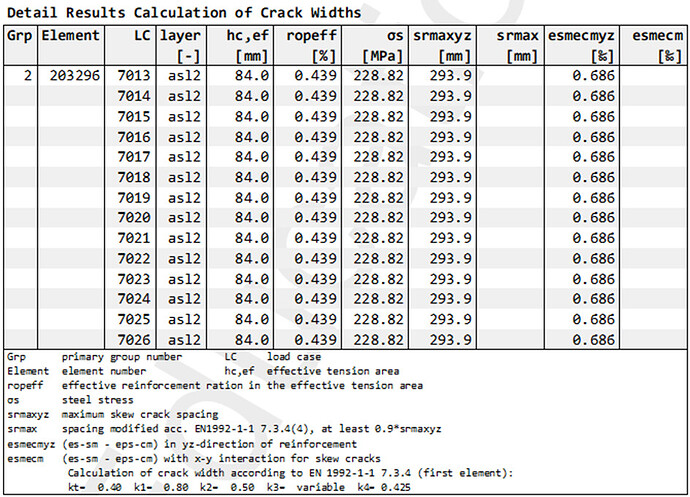

This value matches the result reported by Sofistik.

However, when calculating the maximum crack spacing Sr,max I obtained:

Sr,max=k3⋅c+k1⋅k2⋅k4⋅ϕ/ρp,eff=3.4⋅0.078+0.8⋅0.5⋅0.425⋅0.016/0.00439=0.884 m=884 mm

This does not match Sofistik’s reported value.

It seems that Sofistik might be using ρp,eff expressed as a percentage (0.439) instead of the exact value (0.00439) in this formula, because in that case:

Sr,max=3.4⋅0.078+0.8⋅0.5⋅0.425⋅0.016/0.439=0.271 m=271 mm

Knowing that I used k3=3.4

which is close to Sofistik’s result of 294 mm .and can lead to a closer crack width result to the 0.2 mm limitation I choosed

On the other hand, for the strain difference (εsm−εcm), Sofistik seems to use the exact value of ρp,eff=0.00439 , and my manual calculation matches the software output.

With using ρp,eff=0.00439

εsm−εcm= max{[σs−kt*fct,eff/ρp,eff*(1+αe*ρp,eff)]/Es ; 0.6⋅σs/Es}=0.000686=0.686‰ (=sofistik result)

With using ρp,eff=0.439

εsm−εcm= max{[σs−kt*fct,eff/ρp,eff*(1+αe*ρp,eff)]/Es ; 0.6⋅σs/Es}=0.001107=1.107‰

I could not find any clause in Eurocode that states ρp,eff should be used in percentage form for the crack width calculation. Could you please confirm whether my interpretation is correct, and clarify how Sofistik handles ρp,eff in this context?

Thank you in advance for your support.

Best regards,

Fatma BenBelgacem